Lignin Basics

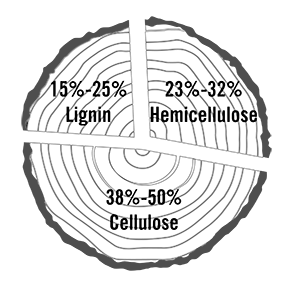

Along with cellulose and hemicelluloses, lignin is one of the three main building blocks of lignocellulosic materials. Lignin is an amorphous, three-dimensional, highly branched polymer structure consisting of three repeating monomer units: p-coumaryl alcohol, coniferyl alcohol and sinapyl alcohol.

The exact lignin structure depends on the feedstock, with softwood, hardwood and other vegetation having different lignin contents and characteristics. Furthermore, the lignin fractionation process significantly affects the properties of the lignin produced.

The majority of lignin is produced from chemical pulping processes, namely kraft and sulphite pulping. The production of lignosulphonates from sulphite pulp mills has been commercialised by numerous companies since the 1930’s. Lignosulphonates have established applications, with total production exceeding million tonnes per annum.

Today, the kraft lignin produced in pulp mills is predominately combusted for energy as part of black liquor. Since 2013, three commercial scale units separating kraft lignin from black liquor have been built. This represents however only a fraction of the total volume of kraft lignin separation potential.

In addition to lignosulphonates and kraft lignin, there are other processes from which lignin can be extracted. For instance, second generation ethanol production yields significant volumes of hydrolysis lignin.

There are considerable opportunities in refining lignin to more value added products. The commercialization has however been a long time challenge. For the first time, the new lignin separation plants have enabled the industrial scale supply of kraft lignin and the demonstration of lignin separation technology, contributing to commercialization of lignin. One of the key objectives of Lignin Club Ecosystem is to accelerate this market development.